Helping businesses transition to low-emission power generation

An industry leader who delivers advanced energy solutions

Integrating modular, flexible, and scalable energy solutions

Implementing high-efficiency CHP systems that reduce energy costs

Ensuring uninterrupted power and heat supply for critical infrastructure

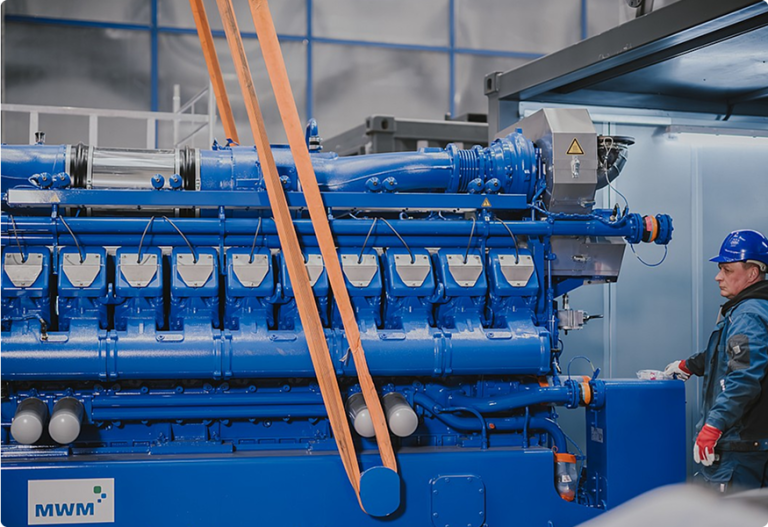

Official Supply & Service partner of the MWM

gas engines producer

OUR STATISTICS

RSE Energy by the numbers

Contact sales300+MW

installed capacity

28+

finished projects

2023

year established

480

fully ready-to-use cogeneration modules

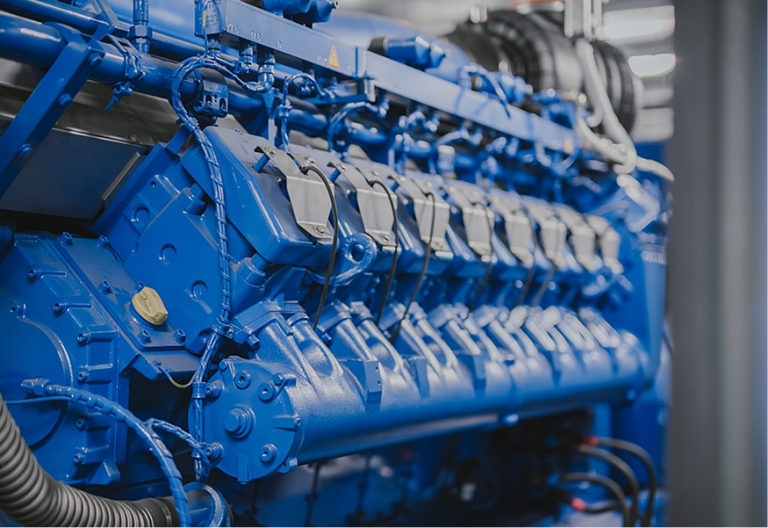

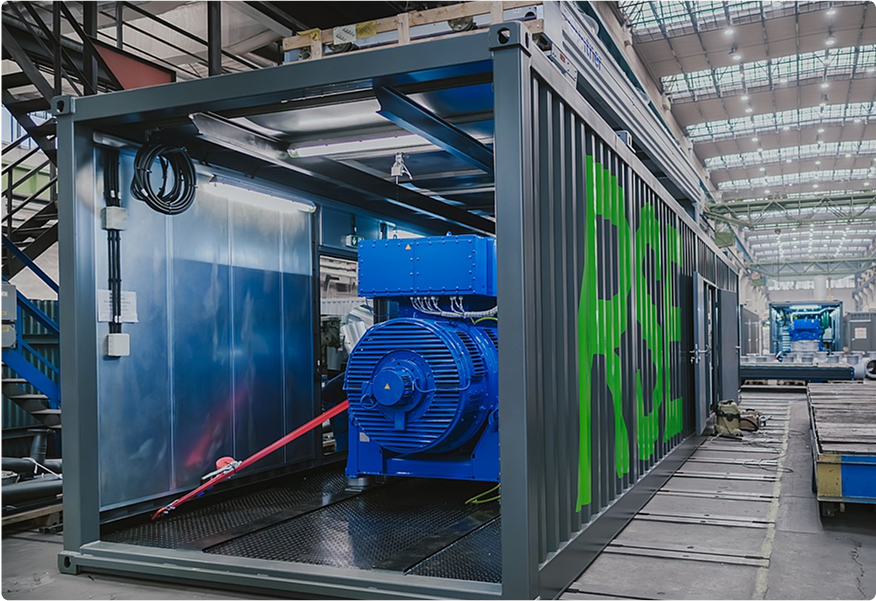

Cogeneration modules

Manufacturing of contenerized CHP units based on MWM gas engines, which ensure continuous work in the production of heat and electricity

Show AllMODEL

We keep you running – service & maintenance solutions

Explore moreSteam and hot water boilers

Production of Exhaust Heat Exchangers to increase the efficiency of CHP units, continues history of the trade mark Prumyslovesta

Show AllHOW IT WORKS?

Cogeneration – The Energy Solution of the Future

Learn moreFuel

combustion

Natural gas, biogas, or other

fuel is used to power a gas

engine or gas turbine.

Electricity

generation

The engine drives a generator that

produces electricity for on-site

use or grid supply.

Heat utilization

Waste heat from the engine, exhaust gases, and cooling system is captured and used for heating, hot water supply, or industrial processes.